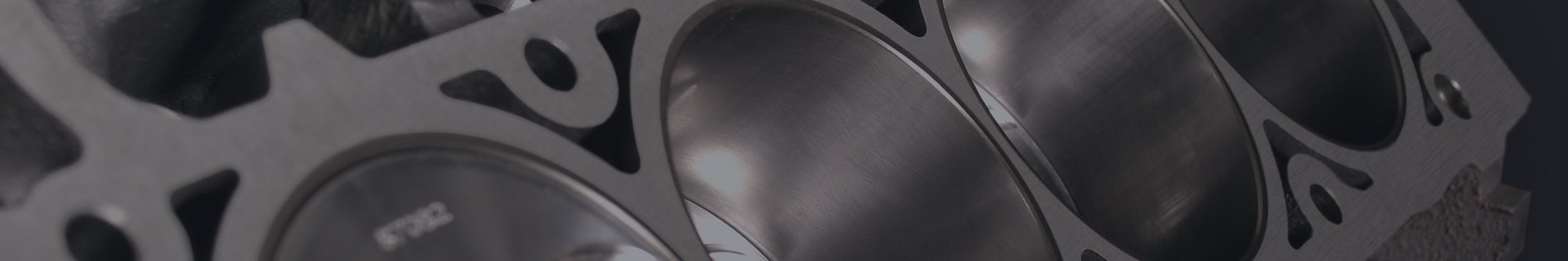

City Motor Supply, Inc. offers CNC boring and milling machine service. The RMC V-40 is fully automated which uses a probe to measure bore tolerance, lines up and bores the block, then decks the block equally on both sides with the correct RMA tolerances. This equipment is able to handle performance precision engine blueprinting and daily production rebuilding.

The Sunnen KGM-1000® KROSSGRINDING System® is the choice for extreme accuracy when honing connecting rods. The KGM system is capable of holding the tightest tolerances in the industry. It can deliver accuracies as good as 0.00001 in. (0,00025 mm) in straightness and .00015 in. (0,00381 mm) in roundness in a production environment.

Low-velocity abrading process uses lower cutting speeds (compared to grinding) and lower pressure to minimize heat, resulting in excellent surface, size, and geometry control. This technology is used in most polishing applications where high loads and tight tolerances are required in today’s applications.

The Sim test machine measures oil flow, oil pressure and compression of the engine. The oil used in the test is preheated to 130 degrees to simulate operating conditions. The oil is triple filtered and forced into the oil galleys at a predetermined pressure. The amount of oil the engine can pass is measured to determine that the tolerances in the engine are to OE specifications. The oil test requires that the reciprocating mass be rotating at approx. 400-500 rpm. After testing, we know that the engine is capable of maintaining oil pressure within factory tolerances. Every cylinder’s compression is also tested.